Composite Production

Complete Integration of Prepreg Composite Production: Molding, Curing, CNC Trimming, Painting, and Assembly for small and medium production runs.

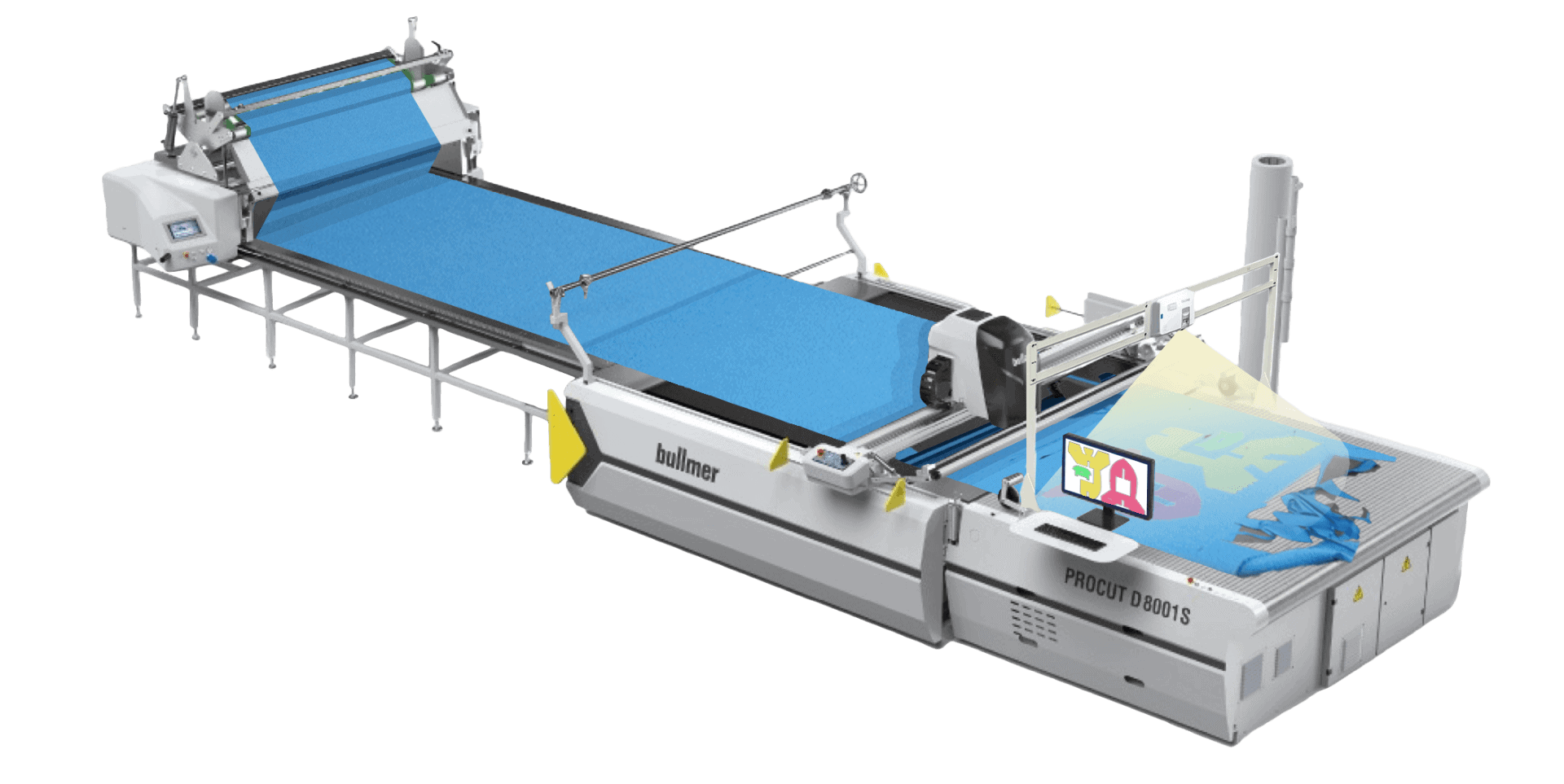

Prepreg

1 Cutting Machine, 4 Ovens, 2 Paint Booths

Parts and Trades

01.

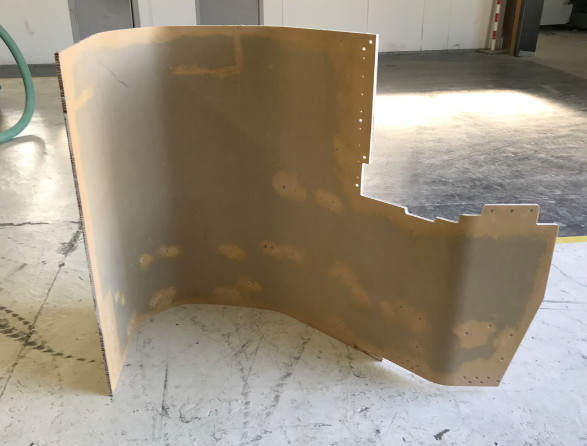

Manufacturing of monolithic and sandwich composite parts

ALMAY offers a comprehensive set of tools to handle the production of prepreg composite parts with curing in ovens. With internal management of tooling design and fabrication, agility and lead times are central to our projects. We also provide expertise in design and draping plans for your parts, tailored to your specifications.

02.

Integrated production

In addition to designing and manufacturing our tooling internally, we also perform trimming, drilling, and machining on our CNC machines. Additionally, we handle modeling and various finishing paints in our two dedicated booths. Our assembly teams then proceed to assemble the various components of your subassemblies, whether composite or metallic.

03.

Series Production

With 4 ovens up to 8 meters long and 4 CNC modeling machines, we can handle a wide range of projects, from single-unit production to several hundred pieces per year. Our teams are trained in all composite technologies and can adapt these technologies according to your needs.